Managing available natural resources

We contribute towards responsible resource management

Photograph taken by Fernando Suviri Iglesias for the 6th Edition of the Sustainability Photography Contest Photographer.

Photography contest for employees organized annually by Abengoa. The jury awarded the first prize and up to three runners.![]()

According to UN data, global demand for drinking water in 2030 will have increased by 40 %1 nd the world population will total 8.4 billion 2 people. Moreover, estimates suggest that by 2030 most of the population from developed or developing regions (including Asia and Africa) will live in cities3, meaning more need for power generation and transmission, access to drinking water and proper waste management and reuse.

Demand for raw materials is also expected to see a sharp increase, which will impact those companies that are heavy consumers of such inputs, as access to natural resources will become steadily more difficult and costly. That said, it will also provide an opportunity for those companies that have processes in place to reuse resources and generate new raw materials from waste, as is the case with Abengoa.

Thanks to its business model and its management and operating processes, Abengoa champions responsible resource management by generating and transmitting clean energy, providing a one-stop water management service, using waste reuse processes and relying also on its research in the field of material recycling and reuse.4.

This chapter describes how Abengoa approaches and carries out its efficient management and use of resources.

Note 1: United Nations Environment Programme (2011). Towards a Green Economy: Pathways to Sustainable Development and Poverty Eradication.

Note 2: United Nations, Department of Economic and Social Affairs, Population Division (2011). World Population Prospects: The 2010 Revision.

Note 3: UN Habitat (2010). State of the World’s Cities 2010/2011 – Cities for All: Bridging the Urban Divide.

Note 4: Further information in the chapter “Business Model” and in its Activities Report.

At Abengoa we apply R&D and innovation to our products and services in response to the real problems affecting our society

R&D and innovation projects geared towards the optimum management of available resources

Abengoa is working on a number of projects to cut consumption of raw materials and which involve innovation in biotechnology and chemical processes.

Biotechnology

In October 2014 Abengoa inaugurated a second-generation (2G) biofuel plant at Hugoton, Kansas, (United States), the world’s first commercial facility of its kind.

The project marks a huge step forward for the company in terms of quality, in that the plant is not only capable of generating biofuel from grain sugar and sugar cane (1G4) but has also started commercial biofuel production from agricultural waste or biomass (2G6). he facility is able to produce up to 95 ML of bioetanol a year from nearly 350,000 t of biomass, thus cutting gasoline consumption by over 60 ML while creating more than 1,300 jobs..

Bioethanol production from agricultural waste is a clear example of how R&D and innovation at Abengoa responds to the new challenges facing society. In this case, the company has developed the cocktail of enzymes needed to convert non-food organic material (cellulosic biomass) into sugar, which is then fermented to produce ethanol.

The Hugoton facility is able to generate 21 MW of energy through its biomass boiler, making it self-sufficient in energy. The electricity generation system was made operational in December 2013 and channels surplus power into the grid.

Note 5: First-generation (1G) biofuels: fuels of biological origin that are obtained in a renewable manner from organic waste. First-generation biofuels are derived directly from farming crops for human consumption and animal feed.

Note 6: Second-generation (2G) biofuels: fuels of biological origin that are obtained in a renewable manner from organic waste. Second-generation biofuels come from non-food crops such as, for example: grain chaff, the organic fraction of municipal solid waste, etc. They require more advanced technology and a more complex process; however, the feedstock has a lower cost and these biofuels have a high potential for reducing emissions with respect to the fossil fuels they substitute, in addition to having the advantage of being able to be produced on marginal lands of low agricultural value.

Enzymes and yeasts

Enzymes are a kind of protein that facilitate and speed up chemical reactions in the human body, from transporting oxygen in the blood to helping the body digest a meal. They act as catalysts of biological reactions.

Yeasts are single-celled microorganisms that are hugely important in industry because of their ability to transform different organic substances, mainly sugar or carbohydrates.

Both enzymes and yeasts are used in biotechnology. They are essential for many traditional processes, such as alcohol fermentation and cheese production, and are also used for a range of industrial purposes, including detergents, stationary, clinical analysis, medicine and biofuels.

Both elements pose a number of limitations when it comes to industrial applications because they are sensitive to changes in temperatures and acidity, prefer certain substrates over others and depend also on the performance of the product they generate. In other words, each yeast or enzyme only works optimally within a specific temperature range and pH value.

Both elements pose a number of limitations when it comes to industrial applications because they are sensitive to changes in temperatures and acidity, prefer certain substrates over others and depend also on the performance of the product they generate. In other words, each yeast or enzyme only works optimally within a specific temperature range and pH value.

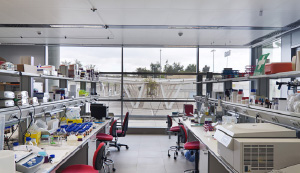

Abengoa Research boasts one of the world’s largest research teams when it comes to enzyme and yeast biotechnology. Work is ongoing at its Campus Palmas Altas laboratories (Seville, Spain) to seek out new and improve existing enzymes and yeasts, while its Fermentation and Separation Technology Center (FSTC) at Babilafuente (Salamanca, Spain) is developing and broadening the company’s capabilities and experience in the production of enzymes and yeasts by optimizing sugar fermentation processes that rely on these elements.

Both centers are coordinating their work through a multi-disciplinary team of scientists and engineers. The team has already built up considerable know-how in developing laboratory-scale biotechnological processes that can then be scaled up to industrial use. This has allowed Abengoa to cement its position as one of the key figures worldwide in the development of industrial biotechnology.

Chemical processes

Scientific breakthroughs and advances in nanotechnology7 are providing extraordinary opportunities in the field of water treatment and desalination, yielding processes that are efficient, cheap and environmentally sustainable.

In the Nano4water8, project, researchers in material physics and organic chemistry and the chemical and water process engineers of both Abengoa and its partners are working together to come up with new nanomaterials intended for water treatment applications.

For example, Abengoa has partnered up with IMDEA Nanociencia, to create a new family of materials9 that can be treated in different ways to provide a wealth of different properties, such as magnetism or hydrophily.

Water

The overriding objective of R&D and innovation in this area is to lower the environmental impact associated with water desalination and treatment processes. To this end, Abengoa is designing more efficient processes to reduce energy consumption, greenhouse gas emissions and the generation of sub-products through valorization.

The task of developing the next generation of desalination plants essentially involves optimizing and intensifying existing facilities through the integration and hybridization of new technologies.

Modifying membranes and developing new materials employed in the reverse osmosis10process will help reduce energy consumption at existing plants.

Valorizing the brine 11generated from the desalination process is also a core objective of the desalination research program. Brine treatment systems will allow the company to produce products in great demand.

The arrival of the next generation of desalination facilities will herald a significant reduction in their environmental impact, thus helping to protect marine biodiversity at plant discharge points.

Main environmental indicators

Abengoa seeks to minimize the environmental impact of its business and its use of resources. To accomplish this, the company invests heavily in developing improvements to its processes in pursuit of optimum efficiency. In 2014, environmental investment and expenses totaled € 26,644 M, up 4 % year-on-year.

The company also relies on training as a means of attaining excellence in its business activities. All employees must be aware of the company’s commitment to efficiency and the environmental impact of its activities. For this reason, environmental training hours have climbed 44 % since 2012 to reach 53,704 in 201412.

Note 7: Nanotechnology: sciences and development techniques that are applied on a nanometric scale, enabling manipulation of material at the atomic, molecular and supramolecular level.

Note 8: Nano4water: new nanotechnology program for water treatment process applications. (+info)

Note 9: Materials known as “covalent organic frameworks” (or COF, for short).

Note 10: Reverse osmosis: water purification technology which achieves the removal of a high percentage of dissolved and undissolved contaminants.

Note 11: Brine: water that contains a high concentration of dissolved salt.

Note 12: Further information in the Chapter “Talent for business success”.

Independent Panel of Experts on Sustainable Development Recommendation 2014

Social and environmental performance

"In order to measure the impact of sustainability policies Abengoa should select a limited number of key performance indicators, both qualitative and quantitative.

In terms of environmental performance Abengoa should move in the direction of explaining the return on investments made, such as the extent of cost reductions, process improvements, product innovation or the positive impact on local communities.

With the example of training activities, this would involve recording how improved skillsets and/or behavior resulted from training rather than just reporting training hours statistics."

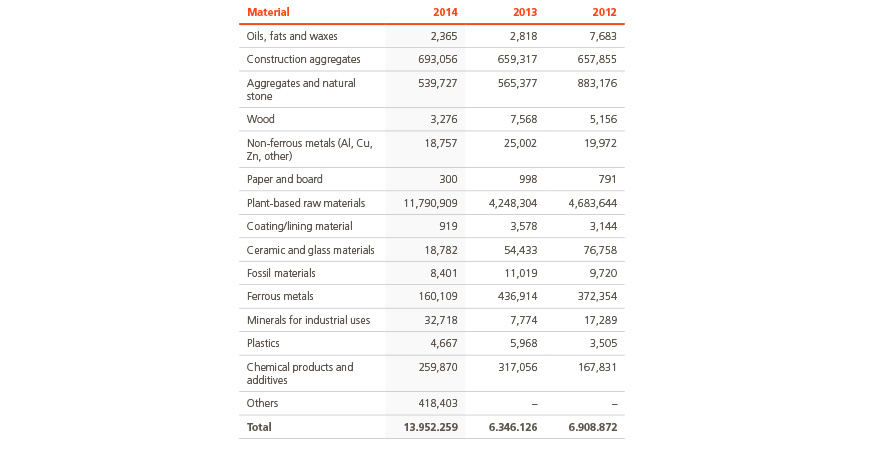

Efficient use of resources

Abengoa is acutely aware that its lines of business are input-heavy and therefore strives to minimize the associated impact. The main focus of its efforts in this regard are the materials it acquires to carry on its business. The company establishes an exhaustive control of the purchases it makes and favors the acquisition of recycled and/or certified materials.

It also requests safety information on the substances it receives from its suppliers, enabling it to gauge the main environmental and health risks involved in handling such materials and the regulatory requirements for their proper transport.

Abengoa treats the optimization of the resources it acquires as the cornerstone of its environmental policy.

Total consumption of materials in 2014 stood at 13,952,259 t, up 54,5 % on 2013. The increase can be put down to the company’s rising consumption of raw plant-based inputs, in turn due to two factors: the start-up of the Hugoton bioethanol plant and increased production at the Indiana bioethanol plant

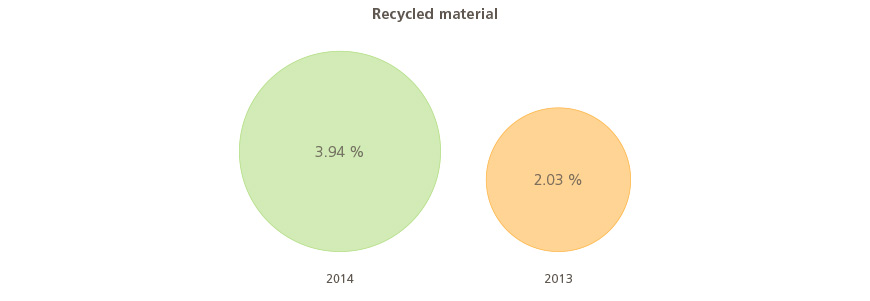

The company also champions the use of recycled and/or certified materials. In 2014, Abengoa used a total of 550,180 t of recycled materials for its processes (3.94 % of all materials used), chiefly plant-based raw materials and molasses.

Some of the raw materials acquired by Abengoa have the following certificates or labels:

- RBSA: the company’s own certification standard enabling it to verify compliance with the sustainability requirements of the European Renewables Directive These include the need to cut greenhouse gas emissions in relation to the original fuel and protect biodiversity by carrying out an exhaustive control of the value chain through life cycle analyses.

- Ecolabel: EU label used to identify products and services that have had their environmental impact reduced through a life cycle analysis, from initial extraction through to elimination as a waste.

- Blue Angel: environmental label launched by the German government for environmentally-friendly products and services.

- FSC: global non-profit organization that champions responsible forest management. The certification identifies the source of the product, ensuring its quality. It also guarantees that the product has been sustainably sourced

Waste management

The expansion of the global economy based on consumption is triggering a huge increase in the generation of waste, making waste management an environmental headache that must be addressed.

Aware of this and also the opportunities it presents, Abengoa has rolled out cyclic mechanisms to minimize the environmental impact through optimum waste valorization.

Valorized waste

Total valorized waste in 2014 amounted to 44,010 tons, equivalent to 35.9 % of the total waste generated.

The most sustainable waste management decision was taken in nearly 30 % of cases.

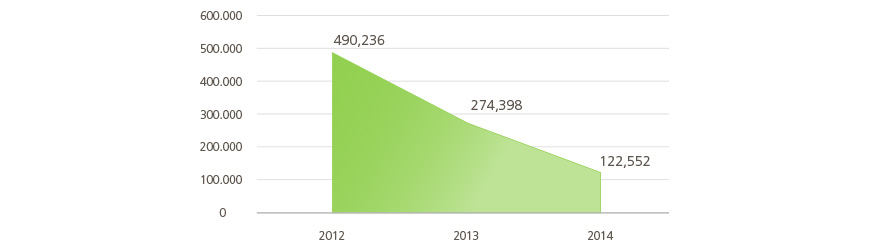

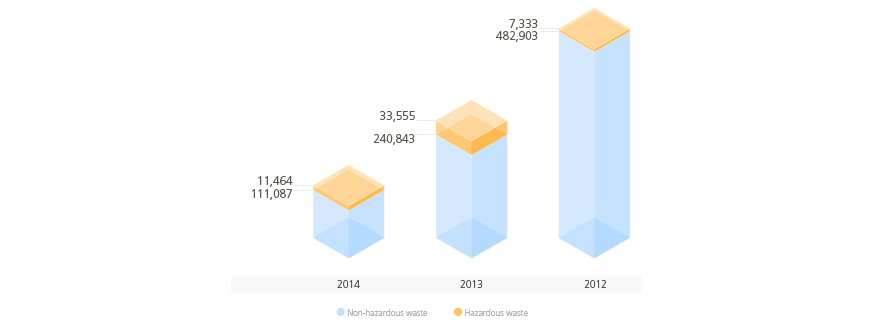

Total waste generated from Abengoa business in 2014 totaled 122,552 tons, 44 % less than in 2013. Only 10 % of the total waste is considered hazardous.

The main kinds of waste generated from Abengoa business are as follows:

Transport of hazardous waste can pose a danger to both human health and the environment. Poor management will entail liability for non-compliance with applicable law. Abengoa ensures this activity is carried out through authorized management companies and thoroughly analyzes the hazardousness of the waste and the destination country. A total of 26 tons of hazardous waste was transported in 2014, mainly in Brazil and Uruguay.

Water: efficient consumption and production of drinking water

Water is a basic natural resource with unequal distribution and access worldwide. Water management at Abengoa therefore focuses on efficient water use, avoiding competition with human consumption and minimizing the impact on protected water bodies.

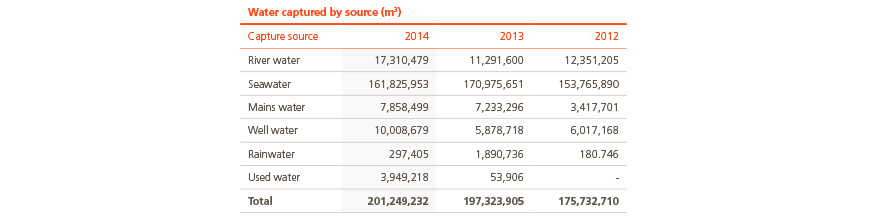

During the capturing stage, Abengoa identifies all its water sources, ensuring that none of them are included on the Ramsar list13 of wetlands. There was no report in 2014 of any especially sensitive source, or of any source in which annual water consumption volume accounted for more than 5 % of the total.

Abengoa’s commitment to efficient water use has required it to shift its focus, with the company now researching and developing technologies that can be applied in regions where water availability affects the company’s business. A prime example of this is the fact that Abengoa Research is now experimenting with molten salts as heat accumulating fluids at its solar thermal power plants. This technology reduces water consumption at these kinds of facility, which are typically located in water-scarce regions.

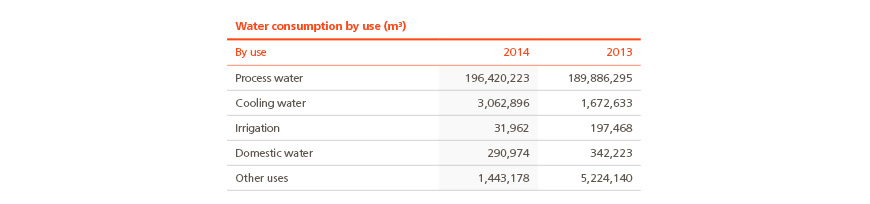

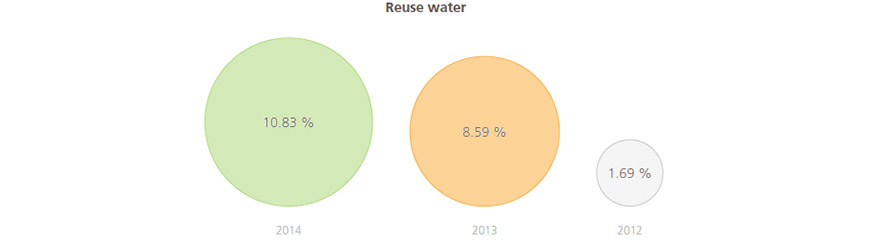

Abengoa is also fully committed to water reuse and to lowering its water consumption. In 2014, reused water accounted for 10.8314 % of the total volume captured by all Abengoa companies.

Photograph taken by Rafael Moreno Chacón for the 6th Edition of the Sustainability Photography Contest.

Photography contest for employees organized annually by Abengoa. The jury awarded the first prize and up to three runners.

![]()

On the subject of reducing water consumption, highlight initiatives for the year included:

- The company’s bioethanol plant in Murcia (Spain) successfully modified its water outlet, lowering tank filling by 4 m3/h. The development cost € 25,200.

- The bioethanol plants in Brazil carried out work to reduce water consumption to 1 m3 per ton of sugar cane processed. The initiative cost € 155,085.

Abengoa also generates drinking water through its desalination plants in regions where water availability is limited. A total of 72.381.117 m3 of desalinated water was produced in 2014.

Note 13: Ramsar List: list of wetlands of international importance published by the Convention on Wetlands, an intergovernmental treaty which serves as a framework for national action and international cooperation in promoting conservation and rational use of wetlands and their resources.

Note 14 This calculation excludes water used in desalination proocesses.

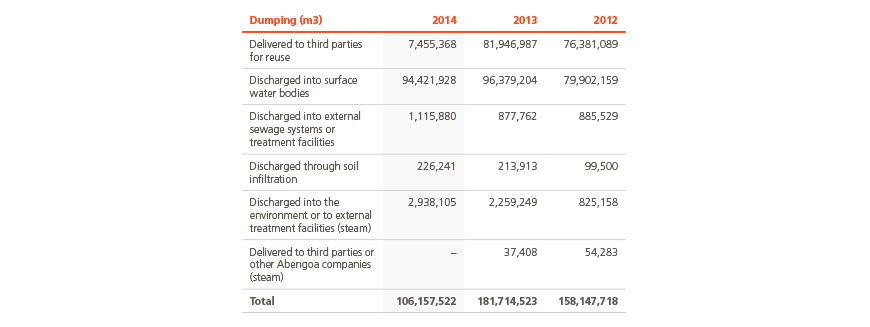

Discharge and spillages

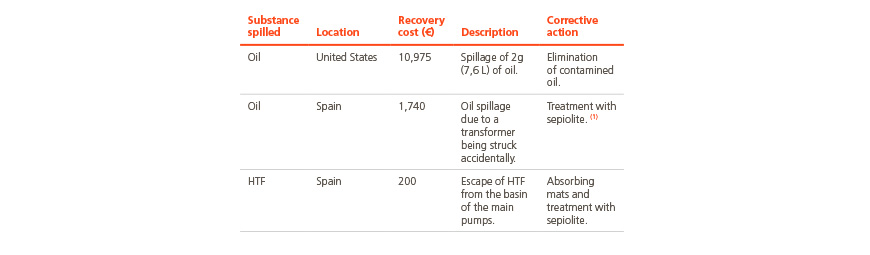

Despite Abengoa’s tight control across all its businesses, certain aspects occasionally fall outside its control.

In case of accidental spills, during 2014 there have been a total of 163 accidents that have not caused any significant damage into the environment. The cost of the actions taken by the company to correct the damage was € 89,500.

The company rolls out initiatives to mitigate the damage caused.

(1) Mineral often used as industrial absorbent beause of its porosity.

To repair the damage caused, Abengoa undertakes to treat used water correctly, meaning it treats it accordingly before discharging it, ensuring that the end quality of the water falls within the legal limits.

Biodiversity

Abengoa’s strategy to protecting biodiversity involves a combination of instruments to prevent, manage and restore the damage caused by its activities.

Before embarking on a project, Abengoa conducts environmental impact studies in order to flag and assess the impact its activity will have on the environment. More specifically, the company analyzes whether and how each of its facilities will impact protected areas, including the flora and fauna affected.

In 2014, Abengoa activities affected a total of 1,128 ha of protected area.

During project construction and operation, the company promotes the use of systems and techniques contributing to organic soil regeneration and thereby helping to reduce fire risk. The company also establishes plans for protecting species of flora and fauna, with a total investment in 2014 of € 797,00015. Additionally, damage repair and remediation initiatives were carried out over the course of the year through an investment of € 61,000.

Note 15 An example of this is maintaining the water profile near the combined-cycle plant being built by Abengoa in Poland, with an investment of € 696,975

Preserving Ecosystems

Abengoa has implemented a program to rescue flora and fauna in the cities of Hermosillo and Nacozari (Mexico), with the aim of mitigating any adverse ecological impact caused by the construction of power transmission lines while helping to preserve biodiversity and maintain a balanced ecosystem within the affected region.

The program commences before the ground is cleared and foundation work gets under way and before the maneuvering and assembly areas are set up. Preliminary work is carried out to rescue any plant life that could be affected by the work if regeneration will prove difficult within the meaning of state regulation16.

The organisms rescued are relocated to a distance of 200 and 300 m from the capture site and are assigned an identification code so they can be subsequently tracked. o determine whether they survived the move. The survival rate tends to be more than 70 %, with this marking an end to the process.

To protect native animal life, including both mammals and reptiles, signs posts were restricted in order to not interfere with their camouflage.

The program culminates with awareness initiatives addressing the importance of environmental protection and reminding workers that they may not capture, damage, or hunt any organism living within the region. Signs are also erected in areas neighboring the site warning of the environmental importance of the area.

Nota 16: According to national regulation NOM-059-SEMARNAT-2010.

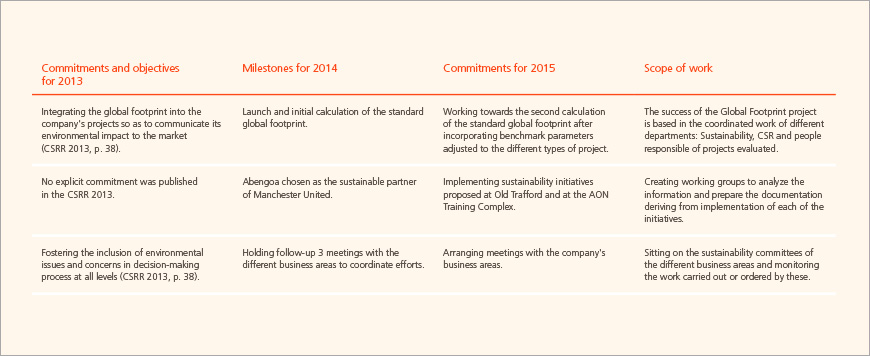

In 2013, Abengoa set out to develop an internal standard referred to as the “Global Footprint", for the purpose of being able to determine the main impacts of its activities, quantify these impacts toward improved management thereof and establish commitments to improved performance.

The standard is materialized in a set of indicators with the capacity to evaluate the impact of a project on the natural, social and economic environment while at the same time enabling the company to anticipate future impact of projects with similar characteristics and set improvement targets.

Abengoa considers that the main impacts of its operations are linked to the following factors:

In the environmental dimension:

- Raw materials used and consumption of recycled materials.

- Water withdrawal, reutilization and efficiency.

- Consumption of primary and intermediate energy and reuse and efficiency.

- Waste generated and valorization.

- Total of GHG emissions generated by scope.

- In the social and economic dimension:

Purchases made from local suppliers.

- Local employees (from the country and region in question) with respect to the total number of employees hired.

- Negative impactson local communities.

- Investment in external social engagement..

- Accident rate and frequency.

In 2014, Abengoa completed the development of the internal norm that includes the procedures and tools needed to calculate the company’s global footprint in accordance with international standards (ISO 14001, ISO 14067, ISO 50001, ISO 26000, SA8000, GRI G4 and OHSAS 18001) and which establishes the reference values for each indicator. These values will be adapted in 2015 to the different project types and locations.

Environmental management systems

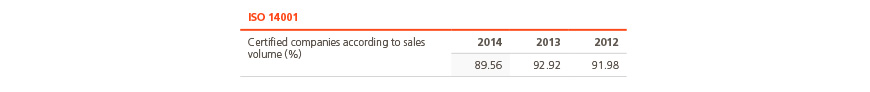

Abengoa implements environmental management systems in all of its companies, in accordance with the international ISO 1400117, standard, in order to prevent and mitigate any environmental risks or negative impacts which inappropriate management thereof might cause.

89.56 % of Abengoa’s companies had a certified environmental management system in 2014

The fluctuation in percentages is due to the creation of new companies. A period of time is needed between their creation and implementation and certification of environmental management systems.

Nota 17: ISO 14001: International certification of environmental management systems.